FOR THE SOUND YOU THOUGHT YOU BOUGHT

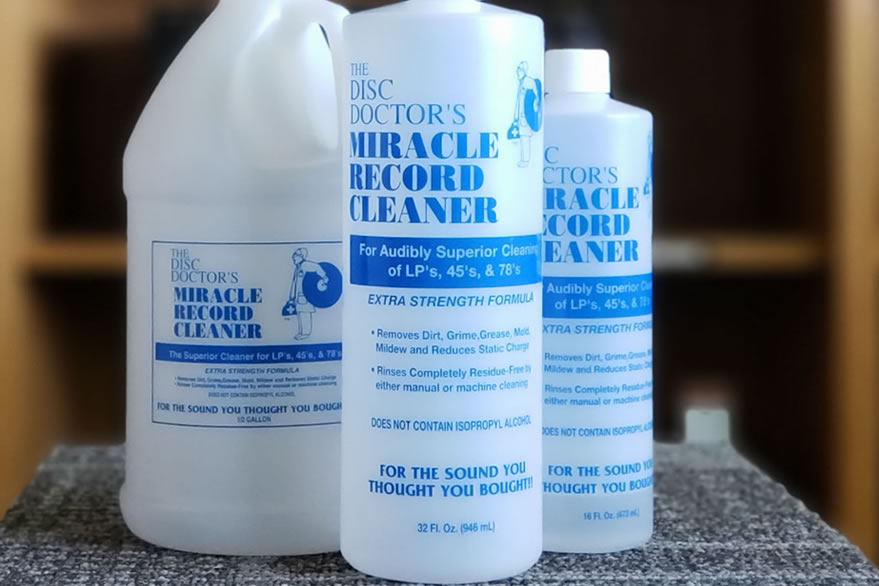

THE DISC DOCTOR'S MIRACLE RECORD CLEANER:

• Safe for repeated use on all types of synthetic plastic discs (vinyl, filled vinyl, styrene and other formulations, such as Victrolac or the phenolic resin playing surface of Diamond Discs) and all types of shellac and acetate recordings.• Readily cleans away all contaminants commonly found on records — gritty, sticky, or greasy, Miracle Record Cleaner performs!

• Cleans away mold or mildew and removes spores to inhibit regrowth!

• Does not contain isopropyl or methyl alcohol or other solvents that can dissolve shellac surfaces and cause the leaching of plasticizers from synthetic plastic pressings making them brittle and subject to excess wear.

• Won't leave any residue on the record after cleaning.

What you need to get started

The Disc Doctor's Miracle Record Brushes, matched to record size and surface, for safe, efficient, wet and dry cleaning.

Distilled water or equivalent

Non Abrasive Lint free drying cloth- 100% cotton baby bath towels are an excellent example

A safe place to air dry your LPs - a common vinyl-covered wire dish drainer unit works great

Preparations

Your work surface should be flat and firm, such as a kitchen table covered with a smooth, heavy plastic tablecloth to protect the record. LP turntable platter mats likewise make excellent work surfaces; using a pair saves having to clean the work surface between sides.

Solution Strength — As purchased, The Disc Doctor's Miracle Record Cleaner is an extra strength solution suitable for cleaning every disc recording you own. Average condition vinyl pressings and well cared-for shellac and acetate discs can be cleaned with a solution of 2 parts cleaner to 1 part distilled water. EXCEPTION: To safely clean pre-1910 shellac pressings use a solution of 1 part cleaner to 2 parts distilled water.

Fill a clean container with distilled or filtered water for rinsing.

Pre-brushing: For excessively dirty shellac or acetate pressings and Edison Diamond Discs, a pre-brushing to remove loose dirt is recommended before wet cleaning.

Cleaning Procedure

1)

Application — Place record flat on work surface. Apply cleaner to a Disc Doctor's Miracle Wet Brush so that the fiber surface is almost saturated with fluid (for an LP-sized brush, ½ tsp (2-3 ml) for the initial wetting and about half as much for subsequent sides). Lightly run the saturated brush around the disc to wet the entire surface. Avoid wetting the record label. Then firmly scrub 1/3 of the groove surface at a time with three back-and-forth sweeps, Apply enough pressure on the brush to ensure good contact without crushing the pad into the grooves. There should have been enough fluid in the brush to provide a small puddle in front of the moving brush. Move this puddle around as cleaning progresses. When cleaning is complete, remove most of the fluid by sweeping it up into the cleaning brush as it is lightly dragged around the disc surface. Remove residual fluid from the groove surface by cotton cloth, vacuum or flat sheet toilet paper. Remove residual cleaner from the brush by gently squeegeeing the upper pile of the pad with the handle of a clean nylon toothbrush or your index finger dampened with a little cleaner. Never try to take the record to complete dryness by scrubbing with cloth, paper, or dry vacuum strips.

2)

Rinsing — Saturate second Wet Brush with distilled water from clean container. Spread water around the disc and scrub as in Step 1. Avoid wetting label. Remove residual rinse water from the grooves with a second cotton square, rinsed vacuum wand or fresh toilet paper. Use the slightly dampened cloth or toilet paper to gently wipe the label. Always remove excess water from labels by patting, not wiping. Any lint from cloth or paper remaining after the disc is completely dry, is readily removed with a clean carbon fiber brush.

3)

Drying — After cleaning the reverse side, allow the record to thoroughly air dry (3-6 min) depending on room humidity and air flow, before playing or sleeving.

4)

Maintenance — When dry, apply a clean Carbon Fiber Brush to vinyl surfaces or a Disc Doctor's Miracle Dry Brush to shellac, acetate & Edison discs. Store in a fresh sleeve. All records should be dry brushed before and after regular use.

Tips for using

When desired, additional scrubbing rinse can be applied using distilled water that contains 1-2 drops of the full-strength cleaner per liter or quart of water.

Several plays may be required to experience the full effect of the cleaning process and to reveal the true playing quality of the disc. Material that deposits on the stylus during this process is readily removed with a stylus brush.

When cleaning pre-1910 or extremely dirty, greasy, or moldy pressings, it may be necessary to repeat the cleaning procedure.

Brushes used to clean shellac discs must not be used on vinyl pressings!

Edison Diamond Discs — Avoid wetting the outer edge and spindle hole (areas where the core is exposed). Also avoid wetting paper labels as the top printed label is glued to the pressed-in underlabel. Immediately sop up any liquid that accidently touches these areas. Never immerse a Diamond Disc. Allow records to air dry for 2-6 hours before storage.

Shellac Pressings — "Dish-warped" records must be cleaned with custom support and gentle handling during cleaning to avoid breakage.

Label Fade — OkeH maroon and Victor Red Seal labels are especially likely to fade. Center-start Pathe' records have etched label areas that must be kept dry or filler pigment will wash away.

Victrolac Pressings — These discs often continue to exude an oily film that will require occasional recleaning.

Common causes of noisy grooves after cleaning and playback:

Noisy surfaces after cleaning and 2-3 plays usually results from these conditons:

1) Need for another distilled/reverse osmosis water source.

2) Not removing enough cleaner prior to the rinse.

3) Not thoroughly rinsing.

4) Static charges induced by over-drying.

5) Or worn, damaged or simply inferior quality vinyl.

Cleaning fluids should be applied to the brush and then dispersed about the disc rather than directly to the record surface. Rinse water can be applied directly to the record surface but the brush should be well-wetted whenever it contacts the disc. The back-and-forth scrubbing motion described in our cleaning procedure, we find, affords a more consistent result than holding a brush down to a rotating record.

Suggestions for using our cleaning method with Vacuum Cleaning Machines

The slot in the vacuum wand of most machines is shaped and sized in such a manner that fluids tend to be evaporated as much as sucked through the tube. This produces sufficient turbulence at the face of the vacuum slot so that fluid is sprayed onto the vacuum strips and the record. This necessitates that the wand be rinsed between wash and rinse steps, slowing the process down.

For VPI and similar machines, we recommend purchasing a second wand and column, dedicating one to the wash cycle and another to the rinse.

Record Cleaning, Vinyl Cleaning Acoustic Sounds

COMPETITIVE PRICES

You'll find no better deal!

QUESTIONS?

Call our friendly staff!

FREE SHIPPING

On orders over $250!

Copyright © 2019 by Acoustic Sounds, Inc.. All Rights Reserved.